Customer Success

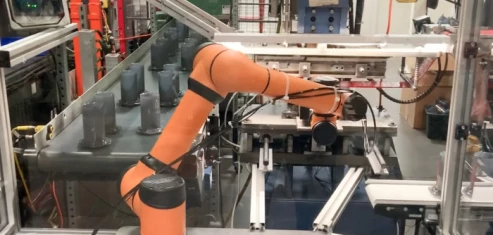

Like most American manufacturers, Behrens has struggled to recruit machine operators. As a result, they had lines sitting idle for multiple shifts in their Winona, MN plant. They turned to Rapid Robotics to help fully staff their lines, improve cycle times, reduce injury rates, and give their human staff a reliable tool to help them do their jobs.

More success stories

-

Automating a traditional pad printing process in less than a week

By “hiring” RMOs at an OpEx friendly monthly rate, Delphon was able to save $20,400 per month and redeploy 8 operators to other jobs

-

Automating pad printing and heat-stamping in a high-mix environment

Enabled Westec to win new business and grow revenue, giving them a $500K+ competitive cost advantage annually

-

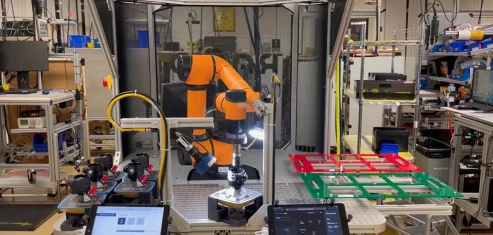

From Impossible to Unstoppable: How Topcon Solved an “Un-automatable” Challenge

Topcon was told over and over that nothing in their facility was a good candidate for robotic automation. With Rapid Robotics, they reduced cycle time on a key operation by more than 90%, saved $55k a year in labor, and repaired a damaged customer relationship.

Want to learn more?

Are you a manufacturer or logistics provider searching for robotic solutions to handle high throughput or operational complexity? Book an intro call with us to be among the first to see what we are launching next. We will answer all of your questions, show you how our newest technology can work for your operations, and even give you guidance on pricing.